Technology

As world leaders in the commercialisation of geopolymer technology, Zeobond is able to bring together cutting edge research from both the academic and commercial sectors. Here, we will showcase the best research literature as it becomes available.

Victorian Science Agenda

Zeobond is working with leading engineering consulting firm Halcrow Pacific, polymer fibre manufacturer Elasto Plastic Concrete and pre-cast concrete products manufacturer Humes to manufacture firbre reinforced concrete tunnel lining segments. Tunnel lining segments are used in applications like outflow pipes for desalination plants and subway systems.

ARC Linkage Grant

Zeobond is supporting fundamental scientific research and training at the University of Melbourne to investigate the long term durability of geopolymer concrete. This work follow on from investigations of old geopolymer structures in the former Soviet Union which were investigated by CEO of Zeobond Jannie van Deventer in 2006.

Investigation of 50 year old geopolymer concretes

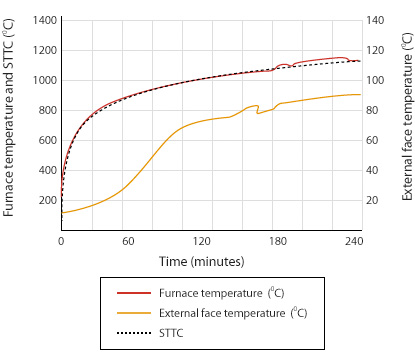

Fire Resistance of E-Crete™

Zeobond has tested the fire resistance of E-Crete according to the Standard Time-Temperature Curve (STTC) heating profile, which is the heating profile specified in the ISO834 Standard. A 4 x 4m panel was installed into a specially designed furnace ast the Fire Engineering Facility of Victoria University of Technology in Werribee for the purpose of fire resistance testing. This test has shown E-Crete™ to perform considerably better than OPC based concrete at high temperatures. The test was turned off at 4 hours, which is the maximum period of time possible under the test protocol, where an equivalent OPC based concrete would typically fail at 2.5 hours. This makes E-Crete pre-cast concrete panels a very cost effective way to achieve fire ratings in pre-cast concrete construction.